Application of High Chromium Cast White Iron in Cement Mill Liner

Add time:2022-12-27

White cast iron has good mechanical properties in the as-cast state, and is suitable for manufacturing wear-resistant castings with complex shapes and large sizes, and has good corrosion and wear resistance in corrosive media. Table 1 lists China and other countries. For the chemical composition standard of KmTBCr26 white cast iron, in order to adapt to a wide range of castings, the alloy range given in the standard is relatively wide.

There is an optimal austenitizing holding time for high chromium cast iron, and this time is related to the original structure state of the workpiece. In order to ensure the stable performance of the workpiece, in addition to strengthening the management of the heat treatment process to ensure process stability, it is also necessary to strengthen the management of the casting process to ensure that the original structure of the workpiece is as consistent as possible.

The impact toughness of high chromium cast iron is closely related to the structure and shape of internal carbides. There are a large number of very uneven carbides in KmTBCr26 cast iron, and the composition changes greatly. Therefore, the impact toughness data of the samples Large fluctuations, no obvious regularity. But generally speaking, when quenching below 980°C, the matrix structure is mainly martensite, and the impact toughness is relatively greatly affected by carbides, and the carbides in the sand-cooled state are more than those in the air-cooled state, so the toughness is lower; When quenching above 980°C, the matrix structure is mainly austenite, and the impact toughness is also mainly determined by the toughness of austenite, while the carbon content in the austenite of the sample in the sand-cooled state is lower than that in the air-cooled state, so the toughness is high.

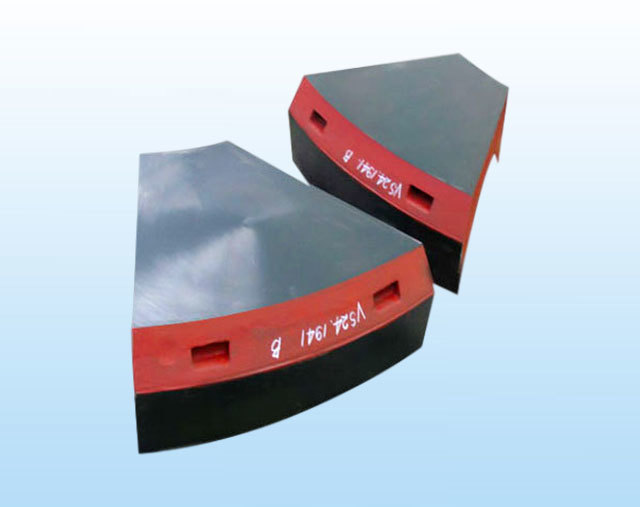

High,Chrome,White,Iron,Grinding,Disk,prices,High,Chrome,White,Iron,Grinding,Disk,For,sale

Previous page

Recommended

2023-01-04