What are the reasons for the burning of the cone crusher bushing

- Categories:News & Information

- Author:

- Origin:

- Time of issue:2023-02-01

- Views:0

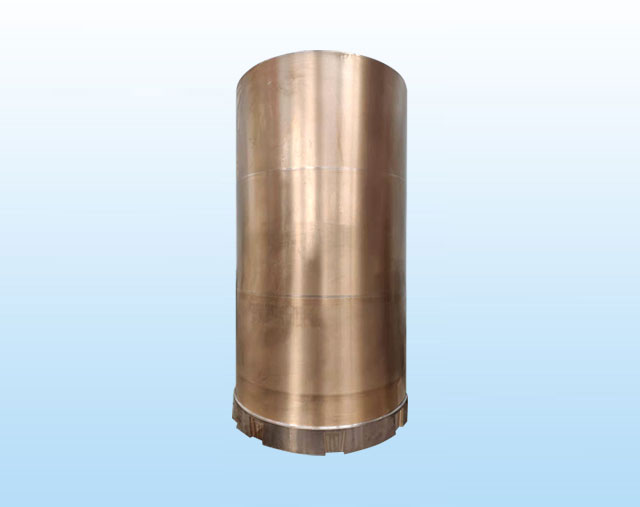

【概要】The cone spindle crusher bushing is used to relieve the wear of the spindle and the fuselage, and prolong the service life of the spindle. Once the spindle bushing is burned out, it must be replaced with a new one, otherwise the phenomenon of shaft holding will occur, which will seriously affect the normal operation of the crusher.

What are the reasons for the burning of the cone crusher bushing

【概要】The cone spindle crusher bushing is used to relieve the wear of the spindle and the fuselage, and prolong the service life of the spindle. Once the spindle bushing is burned out, it must be replaced with a new one, otherwise the phenomenon of shaft holding will occur, which will seriously affect the normal operation of the crusher.

- Categories:News & Information

- Author:

- Origin:

- Time of issue:2023-02-01

- Views:0

The cone spindle crusher bushing is used to relieve the wear of the spindle and the fuselage, and prolong the service life of the spindle. Once the spindle bushing is burned out, it must be replaced with a new one, otherwise the phenomenon of shaft holding will occur, which will seriously affect the normal operation of the crusher. To prevent the burning of the main shaft bushing, the following article will analyze the reasons for the burning of the main shaft bushing of the cone crusher.

1. The main shaft is bent or deformed

The crusher bushing manufacturer tells you that this will significantly reduce the cooperation between the main shaft and the main shaft bushing, especially after the crusher runs hot, causing the copper sleeve to burn out. Therefore, it is necessary to check the status of the spindle regularly.

2. The load is added too fast

. In order to ensure good contact between the new bush and the main shaft, the load should be gradually applied after replacing the bush to avoid burning the copper bush.

3. The quality of lubricating oil is not good

Poor oil quality will reduce the viscosity of the oil film, which will cause the oil film of the main shaft bush to rupture instantly during the mine breaking process and cause the copper sleeve to be burned. Therefore, it should be checked and replaced in time.

4. Insufficient oil

The crusher bushing manufacturer tells you that when the oil pipe is blocked or the pump capacity is reduced, it is easy to cause the copper bushing to lack oil and fail to form an oil film, until the copper bushing is burned. Therefore, check the pipeline and oil pump regularly to ensure sufficient oil.

Five, over iron

Excessive iron will increase the instantaneous load of the crusher, resulting in the rupture of the oil film and the burning of the copper sleeve. Therefore, the metal detector on the feeding belt needs to be kept sensitive and reliable.

6. The matching clearance is not suitable

The gap between the spindle crusher bushing and the spindle should be kept between 1.0 and 1.2 mm, if it is too large or too small, the copper sleeve will be burned. Therefore, the gap between the main shaft bush and the main shaft should be carefully checked during the replacement of the new bush and the use of the bush.

Scan the QR code to read on your phone

Recommended News

Messages

Please leave your valuable comments or suggestions and contact information (email or telephone), so that we can reply to you in time!

QR code

Scan QR code

Copyright © Shenyang Gongda Heavy Equipment Manufacturing Co., Ltd., All Rights Reserved. 辽ICP备05007835号 Powered by 300.cn SEO标签导航