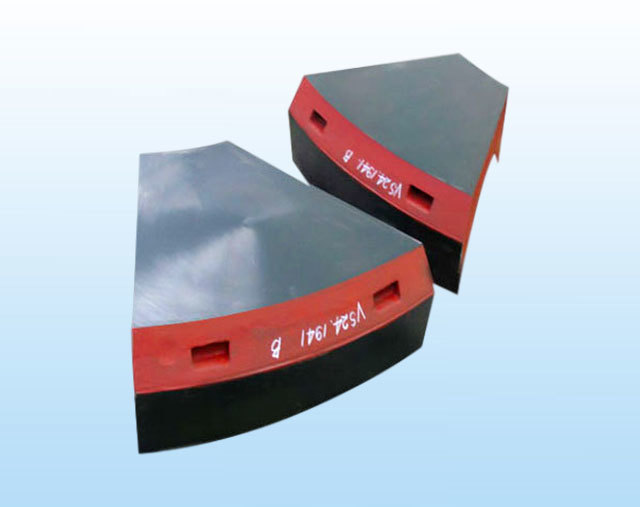

Grinding Process of Grinding Table Segment

Add time:2022-06-30

The grinding process is widely used in industry for its ability to produce high-quality and high-precision surfaces. Achieving good workmanship is more of an artistic skill than a technological achievement. Therefore, appropriate monitoring and control systems should be used to increase the productivity of producing expensive machine tools.

A proper definition of grinding remediation time is critical for overall grinding process optimization and control. If the discs are separated too late, the proper metal removal rate is not achieved, or even worse, the workpiece surface may be damaged. On the other hand, if the dressing is applied too frequently, dressing diamond wear and abrasive disc wear will incur huge costs. When grinding discontinuities, it takes time to use unnecessary dressings, which in turn increases production costs.

In addition to cutting the workpiece surface, it can also be produced by friction in the interaction of vibration between the grinding disc and the workpiece. Research has shown that there is a strong correlation between the transformation and emission of sound and vibration by surfaces. Based on sound and vibration, skilled operation can detect whether the grinding wheel is sharp or dull.

Cheapest,Grinding,Table,Segment,Discount,Grinding,Table,Segment,Low,price,Grinding,Table,Segment

Recommended

2023-01-04