МЭДЭЭ

What is the reason for the rust of the wear-resistant plate of the crusher

The surface of the crusher wear plate is easily oxidized, and the interface is oxidized to reduce the bonding strength of the interface. And for the crusher wear plate that has higher requirements on the quality of the plate, during the heating process

Crusher eccentric bushing repair method

Worn journals are polished: on the premise of ensuring the designed surface roughness, the minimum machining amount is used for processing

Purpose and Benefits of Grinding Table Segment

Grinding Table Segment is used for the manufacture and repair of measuring tools, the grinding of workpieces, the production of high-precision mechanical parts, and the processing of optical instruments.

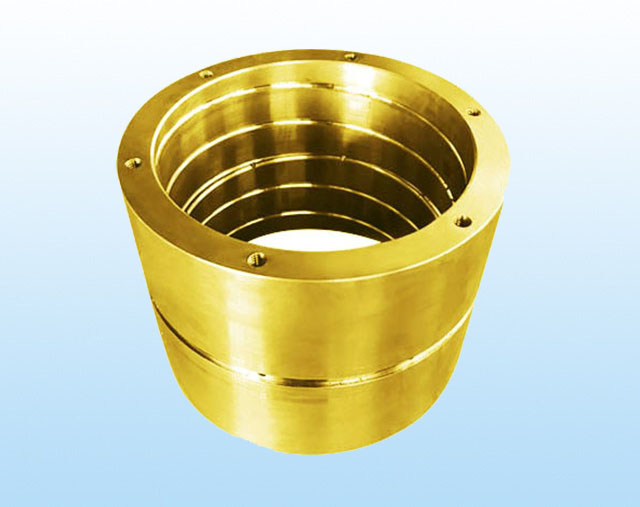

Features of Crusher Eccentric Bushings

The high temperature and pressure generated during high-speed operation will cause wear on the eccentric bushing and tapered bushing, so the material selection of the eccentric bushing needs to be extremely strict

Grinding Process of Grinding Table Segment

The grinding process is widely used in industry for its ability to produce high-quality and high-precision surfaces. Achieving good workmanship is more of an artistic skill than a technological achievement.

How to improve the service life of grinding roller segment for cement mill

Grinding roller segment for cement mill was not widely accepted from the beginning. In the early days, grinding roller segment for cement mill and grinding disc liner had serious wear problems.

How to Improve the Production Efficiency of Grinding Roller Segment for Cement Mill

I believe that all industries using vertical mills must be very familiar with Grinding Roller Segment for Cement Mill. Grinding Roller Segment for Cement Mill is the main part of various vertical mills that is often used to grind materials,

Crusher Eccentric Bushing Installation Steps

Carefully check the clearance between Crusher Eccentric Bushing and the straight bushing of the frame, as well as the upper and lower clearance between the main shaft and its bushing